CATEGORIES

WPC Boards: The Ultimate Choice for Wood Polymer Composite Applications

Wood Polymer Composite (WPC) boards are revolutionizing the way we think about building materials. Combining the best properties of wood and polymers, WPC boards offer a durable, eco-friendly, and versatile option for a variety of applications. In this article, we'll explore why WPC boards are becoming the preferred choice in the market and how they can benefit your next project.

What Are WPC Boards and Why Are They Popular?

WPC boards, or Wood Polymer Composite boards, are engineered materials made using a combination of wood fibers and thermoplastic polymers. This innovative technology results in boards that are waterproof, termite-proof, and fire-retardant, making them ideal for a variety of applications.

Why are they gaining popularity?

- Durability: WPC boards have high mechanical strength, ensuring they last for many years without spoiling.

- Eco-Friendly: Made from recyclable materials, they are an environmentally friendly option.

- Versatility: They can be used in furniture, wall paneling, flooring, and more.

"WPC boards have transformed the way we approach construction and design," says Allen, owner of a leading WPC board factory in China.

How Do WPC Boards Compare to Traditional Wood and PVC Materials?

When compared to traditional wood and PVC materials, WPC boards offer several advantages:

- Resistance to Moisture: Unlike plywood or regular wood, WPC boards are moisture-resistant, making them suitable for kitchens and bathrooms.

- Surface Finish: WPC boards provide a smooth surface that can accept various finishes, including laminate, veneer, and paint.

- Durability: They are less prone to warping, cracking, or deteriorating over time.

Table: Comparison of Materials

| Feature | WPC Board | Wood | PVC |

|---|---|---|---|

| Moisture Resistant | ✅ | ❌ | ✅ |

| Termite Proof | ✅ | ❌ | ✅ |

| Fire Retardant | ✅ | ❌ | ❌ |

| Eco-Friendly | ✅ | ✅ | ❌ |

| Surface Finish Options | ✅ | ✅ | ❌ |

What Types of WPC Boards Are Available in the Market?

The market offers a variety of WPC board types to suit different applications:

- Standard WPC Boards: Ideal for furniture and cabinetry.

- WPC Wall Panels: Used for interior and exterior wall cladding.

- WPC Sheets: Available in various thicknesses for custom applications.

- PVC Marble Sheets: Combine the beauty of marble with the durability of WPC.

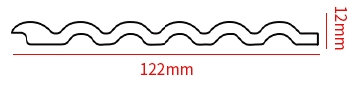

Product Highlight

Check out the XHF01 PS Wall Moulding Panel Easy Install Interior Wall Panels for a versatile option suitable for modern interiors.

Why Choose WPC Boards for Furniture Making?

Furniture made from WPC boards offers several benefits:

- Ease of Workability: WPC boards can be cut, nailed, and screwed just like wood.

- Surface Finishing: They have a smooth surface that allows for laminate, veneer, or paint applications.

- Durability: Resistant to moisture and termites, ensuring the furniture lasts longer.

"Using WPC boards has reduced the risk of damage from moisture and pests," notes Mark Wilson, a procurement officer for a furniture company in the USA.

How Are WPC Boards Applied in Wall Paneling and Cladding?

WPC wall panels and cladding are gaining popularity for both interior and exterior applications:

- Aesthetic Appeal: Available in various designs and textures to enhance the look of any space.

- Easy Installation: Panels are designed for quick and efficient installation.

- Low Maintenance: Requires minimal upkeep compared to traditional materials.

For example, the XHH14 Bathroom Wall Panel PS Decorative Wall Panel offers an excellent option for bathroom renovations.

What Are the Material Strengths of WPC Boards?

WPC boards boast impressive material strengths:

- Mechanical Strength: Capable of bearing significant loads without deformation.

- Fire Retardant: Complies with international safety standards for fire resistance.

- Moisture Resistance: Ideal for humid environments, preventing warping or swelling.

"The strength and reliability of WPC boards have made them a staple in our construction projects," says an architect from Europe.

How Do You Fix and Join WPC Boards Properly?

Proper installation ensures the longevity and performance of WPC boards:

- Fixing Methods: Boards can be fixed using screws, nails, or adhesive.

- Edge Treatment: Edges can be finished smoothly to enhance appearance.

- Joining Techniques: Using appropriate joinery methods to ensure secure connections.

Tips:

- Apply glue evenly in a thin layer to ensure a strong bond.

- Allow at least 1 hour for the adhesive to dry properly.

What Laminate Options Are Available for WPC Surface Finishing?

The smooth surface of WPC boards allows for various finishing options:

- Laminate Sheets: Available in multiple designs and textures.

- Veneers: Provide a natural wood look.

- Acrylic and UV Paints: For a glossy or matte finish.

"We recommend using high-quality laminates to enhance the aesthetic appeal of WPC furniture," advises Allen.

Are WPC Boards Eco-Friendly and Safe for the Environment?

Yes, WPC boards are an environmentally friendly option:

- Recyclable Materials: Made using recycled wood fibers and polymers.

- Low Environmental Impact: Manufacturing process reduces waste.

- Non-Toxic: Free from harmful chemicals.

Environmental Certifications:

- Compliance with international environmental standards.

- Certifications for fire retardant and moisture resistance properties.

How Do WPC Boards Fare in Moisture and Fire Resistance?

WPC boards excel in challenging environments:

- Moisture Resistance: Ideal for areas prone to humidity, such as kitchens and bathrooms.

- Fire Retardant Properties: Reduces the risk of fire spread, ensuring safety.

"Choosing WPC boards has minimized the risk of water damage and fire hazards in our projects," shares Mark Wilson.

Conclusion

WPC boards offer a superior alternative to traditional building materials. Their versatility, durability, and eco-friendly nature make them an excellent choice for a wide range of applications, from furniture making to wall paneling. By understanding the strengths and proper usage of WPC boards, you can enhance the quality and longevity of your construction and design projects.

For more information on WPC wall panels, visit our WPC Wall Panel product page.

Key Takeaways

- Versatile Applications: Suitable for furniture, wall panels, flooring, and more.

- Durable and Long-Lasting: Resistant to moisture, termites, and fire.

- Eco-Friendly: Made from recyclable materials, promoting sustainability.

- Easy Installation: Can be cut, screwed, and joined using regular tools.

- Aesthetic Options: Smooth surface allows for various finishes like laminates and veneers.

For inquiries and more details, feel free to contact us. Explore our wide range of WPC products and take your project to the next level!