CATEGORIES

Unveiling the Truth About Wood Veneer: Advantages, Disadvantages, and Comparisons to Solid Wood

Wood veneer is a popular material used in furniture manufacturing, cabinetry, and interior design. This article provides a comprehensive overview of wood veneer, exploring its advantages, disadvantages, and how it stacks up against solid wood and laminate alternatives. We'll delve into the practical considerations for choosing veneer, helping you make informed decisions for your next project, whether you're a homeowner, interior designer, or construction professional. We, at Xihongbm, as experienced WPC Wall Panel and PVC Marble Sheet manufacturers, want to share our expertise with you.

1. What Exactly is Wood Veneer?

Wood veneer is a thin slice of natural wood, typically less than 1/8 inch (3mm) thick, that is glued onto a substrate material. This substrate can be particleboard, MDF (medium-density fiberboard), plywood, or even another type of wood. Veneer is made by peeling or slicing a thin sheet from a log, much like sharpening a pencil. The result is a product that retains the look and feel of real wood, but with added benefits and a lower cost. Think of it as a way to get the beauty of wood without using a whole piece of wood.

Wood veneer is a thin layer and provides the aesthetic appeal of natural wood without the high cost or resource consumption of solid wood furniture. Veneer is often overlaid onto a less expensive, more stable material.

2. What are the Advantages of Using Wood Veneer?

Wood veneer offers a compelling range of benefits, making it a popular choice for both residential and commercial applications:

- Cost-Effectiveness: Veneer is significantly more affordable than solid wood. This is because a single log can be used to create a large number of veneer sheets, maximizing the use of the natural wood. This means you can achieve the look of exotic or expensive wood species like mahogany without breaking the bank.

- Sustainability: Using wood veneer is a more sustainable practice than using only solid wood. It allows for efficient use of valuable hardwood resources. Because only a thin slice of wood is used, far less wood is required compared to solid wood construction.

- Design Flexibility: Wood veneer offers incredible design versatility. It can be applied to curved surfaces and intricate designs that would be difficult or impossible to achieve with solid wood. Veneer provides the ability to create unique and visually appealing patterns, such as book-matching, where adjacent veneer sheets are arranged to mirror each other.

- Stability: Veneer naturally expands or contracts according to the climate. However, when bonded to a stable substrate like MDF or plywood, veneers are also less prone to warping, splitting, or cracking unlike solid wood, which can be susceptible to these issues due to changes in humidity and temperature.

- Lightweight: Wood veneer furniture is generally lighter than solid wood furniture, making it easier to move and rearrange.

3. Are There Any Disadvantages of Wood Veneer?

While wood veneer boasts many advantages, it's essential to be aware of its potential drawbacks:

- Susceptibility to Water Damage: Certain substrate materials, like MDF and fiberboard, are susceptible to water damage. If the veneer is compromised and water penetrates the substrate, it can cause swelling and irreversible damage. However, many modern veneers are treated with water-resistant finishes to mitigate this risk.

- Potential for Chipping and Scratching: While durable, veneer surfaces can be more susceptible to chipping and scratching than solid wood. However, high-quality veneers with durable finishes can withstand everyday wear and tear. Varnished veneers offer extra protection.

- Repair Limitations: Repairing deep scratches or chips in wood veneer can be more challenging than with solid wood. While minor scratches can often be buffed out, significant damage may require professional repair or replacement of the entire veneer sheet. Wood veneers can be difficult to repair if damaged.

- Cons of wood veneer are fewer, but buyers should be aware of them.

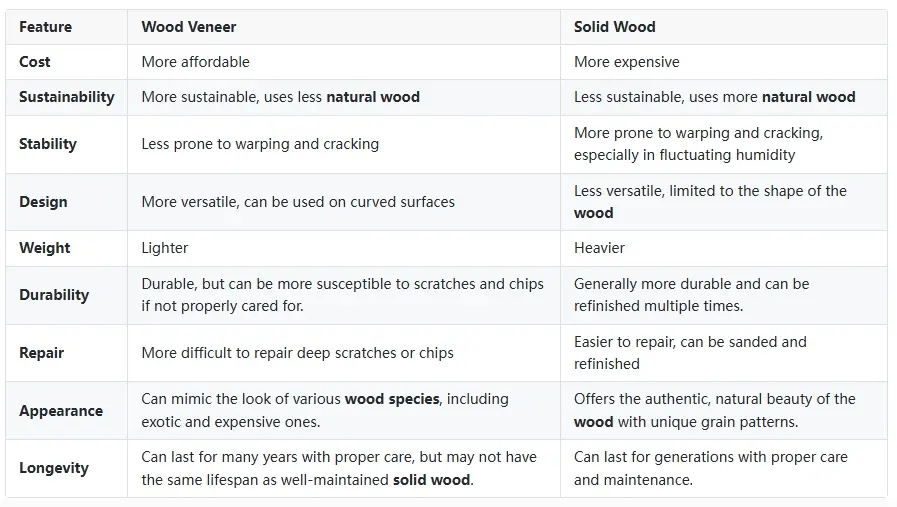

4. Wood Veneer vs. Solid Wood: Which is Better?

The choice between wood veneer and solid wood depends on your priorities and budget. Here's a comparison:

Solid wood furniture is prized for its durability and timeless appeal. It's made from natural wood boards and is generally more robust. However, made of solid wood items are typically more expensive and can warp or crack over time. Purchase a solid wood piece only if you have the appropriate budget. Wood is used in a solid piece.

Wood veneer furniture uses a thin layer of wood over a substrate, offering a cost-effective alternative to solid wood. Veneer provides stability and design flexibility. Wood veneer is a thin covering of fine wood.

5. How Does Wood Veneer Compare to Laminate?

Veneer and laminate are both commonly used as surface materials in furniture manufacturing, but they are very different products:

- Laminate is a synthetic material made of layers of plastic, paper, and resin, printed with a photographic image of wood (or other materials). It is highly durable, water-resistant, and affordable.

- Wood veneer, on the other hand, is made of actual wood. It offers the authentic look and feel of natural wood, which laminate cannot replicate.

While laminate is more resistant to scratches and water, veneer provides a more premium and natural aesthetic. Think of it this way: laminate is a picture of wood, while veneer is wood.

6. What are the Different Types of Wood Veneer?

There are several types of wood veneer, each with its own characteristics and production methods:

- Raw Wood Veneer: This is veneer in its most basic form, without any backing. It requires careful handling and application.

- Paper-Backed Veneer: A thin layer of paper is applied to the back of the veneer for added stability and easier handling.

- Phenolic-Backed Veneer: This type of veneer has a backing made of phenolic resin, making it more durable and water-resistant.

- Wood-on-Wood Veneer: Two layers of wood veneer are glued together, with the grain running in perpendicular directions for increased stability.

- Lay-on Veneer: This is a composite veneer made from multiple thin sheets of wood, often used for creating decorative patterns.

The choice of veneer type depends on the specific application and desired aesthetic. There are many different types of wood and many veneers available.

7. How is Wood Veneer Applied and Maintained?

Applying wood veneer requires skill and precision. It typically involves the following steps:

- Surface Preparation: The substrate surface must be clean, smooth, and free of any imperfections.

- Adhesive Application: A suitable adhesive, such as contact cement or PVA glue, is applied to both the substrate and the veneer.

- Veneer Placement: The veneer sheet is carefully positioned onto the substrate.

- Pressure Application: Pressure is applied evenly across the veneer surface using a veneer press, vacuum bag, or rollers to ensure a strong bond.

- Trimming and Finishing: Excess veneer is trimmed, and the edges are finished. A protective finish, such as lacquer, varnish, or polyurethane, is applied to enhance durability and protect the veneer from moisture and scratches.

Maintenance of wood veneer furniture is relatively simple:

- Regular dusting with a soft cloth.

- Cleaning with a damp cloth and mild wood cleaner.

- Avoiding harsh chemicals or abrasive cleaners.

- Using coasters and placemats to prevent damage from heat and moisture.

- Promptly wiping up spills to prevent water damage.

8. Is Wood Veneer Eco-Friendly?

Wood veneer is generally considered an eco-friendly option, especially when compared to solid wood. Here's why:

- Efficient Resource Use: Veneer utilizes a much smaller amount of natural wood compared to solid wood. A single log can produce a significantly larger surface area of veneer than solid lumber.

- Reduced Wood Waste: The veneer manufacturing process generates less wood waste than traditional lumber milling.

- Use of Sustainable Substrates: Many veneer products use substrate materials made from recycled wood fibers, such as MDF and particleboard.

- FSC Certification: Look for wood veneer products certified by the Forest Stewardship Council (FSC), which ensures that the wood comes from responsibly managed forests.

Wood veneers are also less likely to contain formaldehyde.

9. Where Can I Use Wood Veneer in My Home or Business?

Wood veneer is incredibly versatile and can be used in a wide range of applications:

- Furniture: Coffee table, dining tables, chairs, desks, dressers, and other furniture pieces.

- Cabinetry: Kitchen cabinets, bathroom vanities, and storage units.

- Wall Paneling: Creating accent walls or covering entire walls. Here at Xihongbm, we focus on creating stylish and durable panels, perfect for adding a touch of elegance to any room. Check out our PS Decorative Wall Panel Interior Polystyrene Frame Wall Panel Moulding for inspiration.

- Doors: Interior and exterior doors.

- Flooring: Certain types of engineered wood flooring use a wood veneer top layer.

- Office Furniture

10. Choosing the Right Wood Veneer for Your Project: A Buyer's Guide

When selecting wood veneer, consider the following factors:

- Wood Species: Choose a wood species that matches your desired aesthetic and performance requirements. Popular options include oak, maple, cherry, walnut, and mahogany.

- Veneer Cut: Different cuts, such as rotary, plain-sliced, quarter-sliced, and rift-cut, produce different grain pattern appearances.

- Veneer Thickness: Thicker veneers are generally more durable but also more expensive.

- Substrate Material: Choose a substrate that is appropriate for the intended application. MDF and plywood are common choices.

- Finish: Consider the type of finish that will best protect the veneer and enhance its appearance.

- Budget: Wood veneer prices vary depending on the wood species, veneer cut, thickness, and substrate.

- See our product Multi-Color Feature Ps Wall Panel. Our panels offer various design options, perfect for a modern or traditional look.

A Note From Allen, Your Expert in Wall Panels and Decorative Sheets:

"As a factory owner with 7 production lines, I've seen firsthand the growing demand for high-quality, sustainable, and cost-effective building materials. Wood veneer, along with our WPC and PVC marble sheet products, offers a fantastic solution for achieving beautiful and durable interiors. We export primarily to the USA, North America, Europe, and Australia, and we understand the needs of construction companies, interior designers, architects, and retailers. My team and I are dedicated to providing top-notch products and excellent customer service. Don't hesitate to reach out if you have any questions!" - Allen, Xihongbm

Thinking about Mark Wilson, our typical customer, we at Xihongbm understand his need for quality, competitive pricing, and reliable logistics. We know that communication and timely delivery are crucial, and we strive to exceed expectations in these areas. We also offer all necessary certifications, ensuring our products meet international standards. Our Factory Price Ps Wall Panel is an excellent example of our commitment to quality and affordability.

Key Takeaways:

- Wood veneer is a thin layer of real wood applied to a substrate, offering a cost-effective and sustainable alternative to solid wood.

- Veneer provides design flexibility, stability, and a wide range of aesthetic options.

- While veneer can be susceptible to water damage and scratching, proper care and maintenance can ensure its longevity.

- Wood veneer is an eco-friendly choice, utilizing natural wood resources efficiently.

- Consider wood species, cut, thickness, substrate, and finish when selecting veneer.

- Wood veneer is a versatile choice for many designs.

- Genuine wood veneer offers natural beauty.

- Applying wood veneer is a complex process best left to professionals.

- Wood veneer furniture is made using this thin layer of wood.

- Thin sheet of wood is the defining feature of veneer.

We hope this comprehensive guide has answered your questions about wood veneer. If you're looking for high-quality WPC wall panels or PVC marble sheets, please explore our website, Xihongbm, for more information.