CATEGORIES

PVC UV Marble Sheets: The Ultimate Guide to Waterproof, High Gloss Wall Panels for Bathrooms and Kitchens

Welcome! If you're looking for a modern, stylish, and practical solution for wall coverings, especially in areas like bathrooms and kitchens, you've come to the right place. This article dives deep into PVC UV Marble Sheets, also known as PVC marble wall panels. We'll explore why these marble sheet alternatives are gaining immense popularity, their benefits over natural marble, their features like being waterproof and having a high gloss coating, and what to look for in a reliable supplier. As Allen, owner of a factory specializing in WPC Wall Panels and PVC Marble Sheets, I want to share insights that help buyers like Mark Wilson navigate the market, understand quality, and make informed decisions. This guide is packed with practical information, addressing key concerns from installation to certifications, ensuring you get the best value and performance for your interior decoration projects.

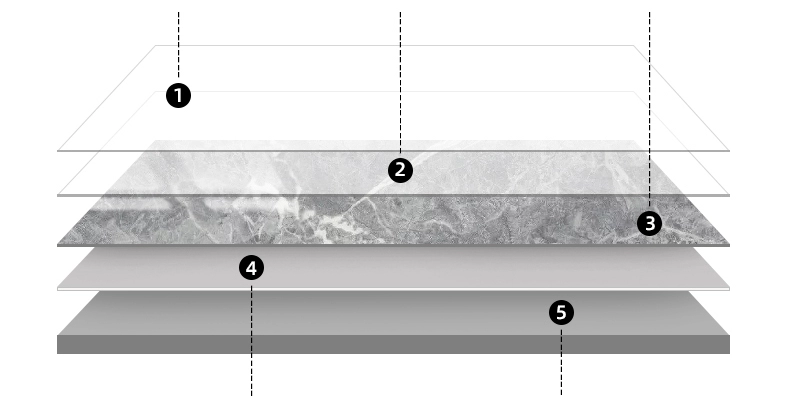

1. What Exactly is a PVC UV Marble Sheet Wall Panel?

Let's start with the basics. A PVC UV Marble Sheet is essentially a decorative wall panel designed to mimic the look of natural marble, but it's made primarily from PVC (Polyvinyl Chloride) resin and calcium carbonate powder. The "UV" part refers to a special ultraviolet coating applied to the surface. This coating is crucial – it cures instantly under UV light, creating a hard, protective layer that enhances scratch resistance, provides a beautiful high gloss finish, and protects the printed marble sheet pattern underneath from fading. Think of it as a high-tech slab of engineered beauty.

These panels are often called UV marble sheets, PVC marble wall panels, or sometimes faux marble sheets. They are a type of architectural decorating material rapidly becoming a go-to choice for interior design, offering the exquisite beauty of natural marble without the associated high cost and installation challenges. They provide a seamless, grout-free finish, making them an excellent wall paneling solution. Our factory produces these marble sheets in standard sizes like 1220x2440mm, often with a thickness around 3mm, but customization is always an option depending on project needs.

The core material blend ensures the PVC marble sheet is lightweight yet sturdy. The manufacturing process involves extruding this base material and then applying a decorative film or print that replicates various marble patterns – from classic Carrara to dramatic Emperador. The final UV coating step locks in the design and provides that signature sheen and protection, making the marble sheet ready for diverse applications.

2. Why are PVC Marble Sheets a Smart Alternative to Natural Marble?

Natural marble is undeniably beautiful, but it comes with significant drawbacks, especially for large-scale projects or budget-conscious buyers like Mark. This is where PVC marble sheets truly shine as a practical and cost-effective alternative to natural marble. From my experience as a manufacturer dealing with global clients, the shift towards engineered materials like PVC marble is driven by compelling advantages.

First, let's talk cost. Real marble is expensive to quarry, transport, and install. PVC marble sheets are much more affordable, often costing a fraction of the price per square foot. This allows developers, designers, and homeowners to achieve a luxurious look without breaking the bank. Secondly, installation is far simpler. Natural marble slabs are heavy, require specialized cutting tools, and demand skilled labor, adding significantly to project time and costs. PVC marble sheets, being lightweight, can be cut with standard tools and installed relatively quickly, even adhering directly over existing tiles in some cases.

Beyond cost and ease of installation, PVC marble sheets offer superior performance in certain aspects. Natural marble is porous and prone to staining and etching, requiring regular sealing and careful maintenance. PVC marble, especially with its UV coating, is non-porous, highly resistant to stains, and incredibly easy to clean – usually just needing a wipe with a damp cloth. This low-maintenance aspect is a huge selling point for end-users and reduces long-term ownership costs.

| Feature | Natural Marble | PVC UV Marble Sheet |

|---|---|---|

| Cost | High | Low to Moderate |

| Weight | Very Heavy | Lightweight |

| Installation | Difficult, requires specialists | Easy, faster, DIY potential |

| Maintenance | High (sealing required) | Low (easy to clean) |

| Water Resistance | Porous, susceptible to damage | Highly Waterproof |

| Stain Resistance | Prone to staining/etching | Highly Stain-resistant |

| Durability | Can chip/crack | Durable, scratch resistant |

| Design Options | Limited by nature | Vast, consistent patterns |

| Eco-Friendliness | Quarrying impact | Often uses recyclable PVC materials |

This table clearly highlights why PVC marble sheets present such a compelling value proposition in modern home construction and renovation.

3. Are PVC Marble Wall Panels Truly Waterproof for Bathrooms and Kitchens?

This is a question I hear frequently from buyers like Mark, whose customers often need reliable solutions for wet areas. The answer is a resounding yes! One of the standout features of PVC marble wall panels is their excellent waterproof nature. Unlike materials like drywall or even some types of wood wall panels, PVC itself is inherently impervious to water. It doesn't swell, warp, rot, or degrade when exposed to moisture.

This makes PVC marble sheets an ideal choice for demanding environments such as bathroom walls, shower wall panels, kitchen backsplashes, and even laundry rooms – areas prone to moisture. The seamless installation, often using an interlock system or adhesives that create a watertight seal, further prevents water from penetrating behind the wall panel. This significantly reduces the risk of mold and mildew growth, contributing to a healthier indoor environment and protecting the underlying wall structure.

The protective UV coating adds another layer of defense, ensuring that water simply beads off the surface. This inherent waterproof quality, combined with being easy to clean, makes PVC marble sheets a highly practical and hygienic choice for any space where water exposure is common. For homeowners and property managers, this means less worry about water damage and easier maintenance compared to traditional tiled surfaces, which rely heavily on the integrity of grout lines (a common point of failure). These PVC wall solutions offer peace of mind.

4. How Does the UV Coating Boost PVC Marble Sheet Durability and Appearance?

The UV coating on a PVC marble sheet isn't just a final touch; it's a critical component that significantly elevates both the performance and aesthetics of the wall panel. As a manufacturer, we invest heavily in the quality of our UV coating process because we know it directly impacts customer satisfaction and product longevity. Mark, when you're evaluating suppliers, asking about their UV coating technology is a smart move.

Functionally, the UV coating acts as a tough shield. It cures under ultraviolet light to form a hard, cross-linked layer that dramatically increases the marble sheet's resistance to scratches, abrasions, and daily wear and tear. This is particularly important in high-traffic areas or spaces like kitchens where the walls might be bumped or scraped. The coating also provides protection against chemical cleaners and prevents stains from setting in, making the surface non-porous and hygienic. Furthermore, it offers UV resistance, preventing the underlying marble pattern from fading over time due to sunlight exposure. This ensures the decorative wall panel retains its vibrant look for years.

Aesthetically, the UV coating is responsible for that stunning high gloss finish that mimics polished natural marble. This reflective surface bounces light around the room, making spaces feel brighter and more expansive. The coating enhances the depth and clarity of the printed marble vein patterns, giving the PVC marble sheet a more realistic and luxurious appearance. While high gloss is popular, different finishes like matte or satin can also be achieved depending on the specific UV formulation and application process, offering design flexibility. This coating truly transforms a basic PVC panel into a sophisticated decorative element.

5. What Are the Key Advantages of Using PVC Marble Sheets for Interior Decoration?

For procurement officers like Mark Wilson, understanding the core benefits of a product is key to selling it effectively to clients like construction firms and interior designers. PVC marble sheets offer a compelling package of advantages that make them suitable for a wide range of interior design projects.

Here's a breakdown of the main benefits:

- Aesthetic Versatility: PVC marble sheets come in an enormous variety of colors, patterns, and vein styles, accurately replicating different types of natural marble and even offering unique, custom designs. This allows designers to achieve almost any desired look. We even produce stunning 3D effect marble sheets that add incredible depth.

- Cost-Effectiveness: As discussed, they are significantly cheaper than real marble in terms of both material cost and installation labor. This makes high-end looks accessible for more projects.

- Waterproof Performance: Ideal for wet areas like bathrooms, showers (shower wall panel applications), and kitchens, preventing water damage and mold growth.

- Durability and Longevity: The robust PVC core combined with the protective UV coating makes these wall panels resistant to scratches, impacts, stains, and fading. They are built to last with minimal maintenance.

- Ease of Installation: Lightweight and easy to cut and handle, significantly reducing installation time and complexity compared to traditional materials. Many systems feature an interlock design for quicker fitting.

- Low Maintenance: No sealing required. Cleaning is simple – just wipe with a damp cloth and mild detergent. This is a major plus for both residential and commercial applications. They are practically maintenance-free.

- Hygienic Surface: The non-porous, seamless surface harbors fewer bacteria and is easier to sanitize than tiled walls with grout lines.

- Eco-Friendly Potential: Many PVC marble sheets are made using recyclable PVC materials, and their durability means less frequent replacement, contributing to sustainability efforts. We prioritize using environmentally friendly materials in our production.

These combined benefits make PVC UV marble sheets a powerful tool for creating beautiful, practical, and long-lasting interior spaces, offering excellent value for homeowners, developers, and designers alike. They provide a modern solution for wall paneling challenges.

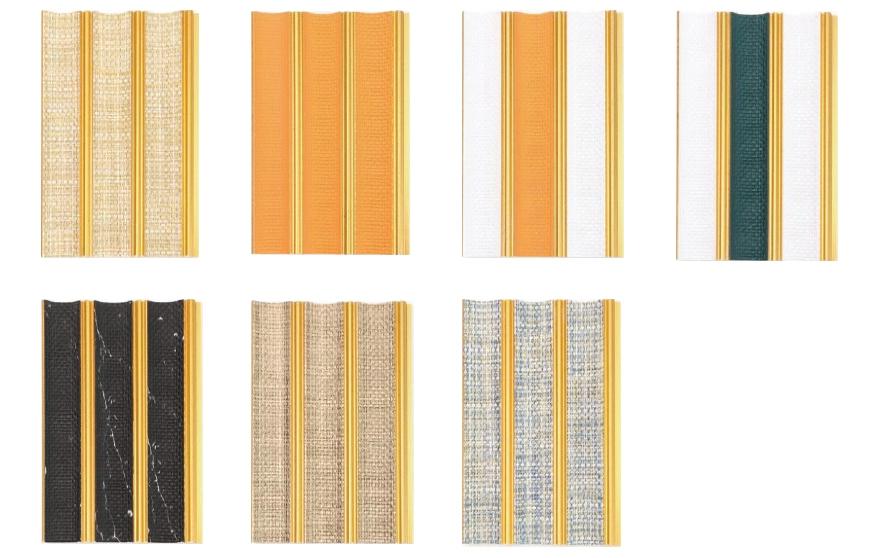

6. Can PVC Marble Sheets Be Customized? Exploring Design Flexibility

Absolutely! Customization is one of the exciting aspects of working with PVC marble sheets, and it's something we, as a factory supplier, pride ourselves on offering. While we maintain a vast catalog of popular marble sheet designs – replicating everything from classic white Carrara to bold black Marquina – we understand that sometimes a project requires something unique.

The customization potential stems from the manufacturing process. The marble look is achieved by applying a high-resolution printed film or direct printing onto the PVC base before the UV coating is applied. This means, theoretically, almost any design, pattern, or color can be created. If an architect or designer has a specific marble slab image they want to replicate, or even a completely bespoke pattern or graphic, it's often feasible to produce custom PVC marble sheets to match, provided minimum order quantities are met.

Beyond the visual pattern, customization can sometimes extend to other aspects:

- Size: While standard sizes like 1220x2440mm (4x8 ft) are common, custom dimensions might be possible for large orders to minimize waste or fit specific architectural features.

- Thickness: The standard 3mm is popular for wall applications, but variations might be requested for different needs.

- Finish: Although high gloss is the most common due to the UV coating, alternative finishes like matte or satin could potentially be developed for specific projects.

- Matching Trim: We can often supply coordinating trim pieces and profiles to ensure a professional finish around edges and corners.

For buyers like Mark, offering customization options can be a significant competitive advantage when dealing with discerning clients. It's always worth discussing specific customization needs with your supplier early in the project planning phase. We encourage clients to find details and price on standard options first, then explore how we can customize further.

7. Is Installing PVC Marble Wall Panels a DIY-Friendly Project?

One of the major appeals of PVC marble wall panels is their relative ease of installation compared to traditional materials like ceramic tile or natural marble. While a professional finish is always recommended, especially for large or complex projects, many aspects of installing PVC marble sheets are indeed DIY-friendly for a competent homeowner.

The lightweight nature of the PVC wall panel is a key factor. Unlike heavy stone slabs, PVC marble sheets can be easily handled and positioned by one or two people. They can typically be cut using standard woodworking tools like a circular saw with a fine-toothed blade or even a utility knife for thinner sheets. This eliminates the need for specialized wet saws and the mess associated with cutting tile or stone.

Installation methods usually involve applying a suitable adhesive (like a polyurethane construction adhesive) to the back of the marble sheet and fixing it directly to the prepared wall surface – which could be drywall, plaster, or even existing tiles (if sound and clean). Some PVC marble wall paneling systems might feature tongue-and-groove or interlock edges for even simpler alignment and a more seamless look. Finishing often involves using color-matched silicone sealant in corners and edges, especially in wet areas like bathrooms, to ensure a watertight seal. The process is generally faster and cleaner than traditional tiling, making it easy to install.

However, proper wall preparation is crucial for a good result. The wall surface must be clean, dry, and flat. Any imperfections should be addressed before installation. While the process is simpler, attention to detail is still required for cutting accurately, ensuring panels are level, and applying adhesive correctly. For those less confident in their DIY skills, hiring a professional ensures the best possible outcome and leverages the full aesthetic potential of the PVC marble sheet.

8. How to Find a Reliable PVC Marble Sheet Supplier? Key Considerations for Buyers.

For Mark Wilson and other procurement professionals, finding the right supplier is critical. It's not just about price; it's about reliability, quality, and communication – addressing those key pain points Mark often faces. Sourcing from developing countries like China offers cost-effective advantages, but requires due diligence. Here’s what to look for in a PVC marble sheet supplier:

- Factory Direct vs. Trading Company: Dealing directly with a factory like ours (Xihongbm) often means better pricing, more control over customization, and direct communication with the production source. Trading companies can add value but might introduce communication layers and markups. Ask potential suppliers about their status – are they the manufacturer? Can you visit the factory?

- Production Capacity & Experience: How long have they been producing PVC marble sheets and related products like WPC wall panels? Do they have sufficient production lines (we have 7) to handle your order volume and meet deadlines? Experienced suppliers are more likely to have robust quality control systems.

- Product Range & Quality: Evaluate their standard range of marble sheet designs. Request samples to assess the print quality, the UV coating finish (gloss level, smoothness), the panel rigidity, and the overall feel. Look for consistency across samples. Do they offer different types like 3D UV marble sheets or standard UV marble sheets?

- Communication & Responsiveness: This is crucial, especially given Mark's pain point. Is the sales representative knowledgeable (even if not deeply technical)? Are they responsive to inquiries? Is their English proficiency adequate for clear communication? Efficient communication prevents misunderstandings and delays.

- Certifications & Testing: Ask for relevant certifications upfront (more on this next). A reliable supplier will readily provide documentation for fire safety, environmental standards, etc.

- Logistics & Payment Terms: Discuss shipping options (FOB, CIF), lead times, packaging standards (to prevent damage during transit), and payment methods. Ensure these align with your company's requirements and risk management policies. Transparency in logistics is key to avoiding shipment delays.

- References & Reputation: Check online reviews, ask for references from buyers in your region (USA, Europe, Australia), or meet them at industry exhibitions – a great way to gauge their professionalism and see products first-hand.

Building a relationship with a trustworthy supplier takes time but pays off in the long run through consistent quality and smoother transactions. Don't be afraid to ask detailed questions and verify information.

9. Quality Control and Certifications: What to Demand from Your PVC Marble Sheet Supplier?

This is perhaps the most critical area for buyers like Mark, directly addressing concerns about quality consistency and the risk of fraudulent certifications. As a reputable factory supplier, we understand the importance of rigorous quality control (QC) and verifiable certifications.

Insist on understanding the supplier's QC process. This should cover:

- Raw Material Inspection: Ensuring the PVC resin, calcium carbonate, and other additives meet specifications. Using high-quality raw PVC materials is fundamental.

- In-Process Checks: Monitoring extrusion parameters, printing alignment, and UV coating application during production.

- Finished Product Testing: Regularly testing samples for dimensional accuracy (thickness, size), surface quality (scratch resistance, gloss level, adhesion of the coating), color consistency, waterproof integrity, and impact resistance.

Regarding certifications, demand copies and, if possible, verify their authenticity through the issuing body's website or contact information. Key certifications for PVC marble sheets often include:

- Fire Safety Ratings: Crucial for building codes. Look for ratings like ASTM E84 (for North America) or EN 13501-1 (for Europe). Different classifications (e.g., Class A, B, or C / B-s1, d0) indicate performance in flame spread and smoke development.

- Environmental Certifications: Certifications like ISO 14001 (Environmental Management System) indicate the factory's commitment to sustainable practices. Look for declarations regarding volatile organic compound (VOC) emissions (e.g., FloorScore or similar) and whether the product uses recyclable materials or is environmentally friendly.

- Quality Management System: ISO 9001 certification demonstrates the supplier has a structured approach to quality management.

- Specific Chemical Content: Compliance with regulations like RoHS (Restriction of Hazardous Substances) or REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe ensures the product is free from certain harmful substances.

Never accept certifications passively. Discuss them with the supplier, understand what they mean, and perform your own verification if doubts arise. A transparent supplier will welcome this scrutiny as it builds trust. Occasional third-party inspections before shipment can also be a worthwhile investment for large orders. This diligence protects your business and ensures the wall panel products you sell meet safety and quality standards.

10. Beyond Walls: Other Applications for Versatile PVC Marble Sheets?

While PVC marble sheets are primarily marketed as wall panels for interior decoration, their versatility extends to several other applications, offering designers and builders creative solutions. Their properties – waterproof, durable, easy to clean, and aesthetically pleasing – make them suitable for various surfaces.

Here are some examples:

- Ceiling Panels: Lightweight PVC marble sheets can be used to create stunning, reflective ceilings, adding a touch of luxury and brightness to rooms. This is particularly effective in commercial spaces like hotel lobbies or restaurants, but also works well in residential bathrooms and kitchens.

- Furniture Surfacing: Thinner PVC marble sheets or laminates can be applied to furniture surfaces like tabletops, cabinet doors (kitchen cabinets), shelving units, and countertops (though caution is advised for high-wear counter surfaces – specific countertop-grade materials are usually better). This allows for coordinated designs where furniture matches the marble wall panels.

- Feature Elements: Use PVC marble sheets to create decorative features like fireplace surrounds (ensure compliance with heat clearances), bed headboards, bar fronts, or accent sections within a larger wall paneling scheme. 3D wall effects can be particularly striking here.

- Commercial Applications: Beyond homes, PVC marble sheets are excellent for retail store displays, reception desks, elevator interiors, partitions, and decorative elements in hospitality settings due to their durability and easy maintenance.

- Wet Room Linings: Their excellent waterproof nature makes them suitable for fully lining wet rooms or shower enclosures, providing a seamless and grout-free alternative to tiles. The PVC Film Marble Sheet offers various patterns perfect for these applications.

Exploring these alternative uses can open up new possibilities for interior design projects. When considering non-standard applications, always ensure the specific PVC marble sheet product is suitable for the intended use, particularly regarding potential wear, heat exposure, or structural requirements. Discussing your ideas with your supplier can provide valuable guidance. The adaptability of PVC marble sheets truly makes them a multi-functional decoration material. We also offer complementary products like WPC Wall Panel and XHA01 PS Wall Panel Small Size Color Multiple Choices PS Decorative Wall Panel which can be used alongside PVC marble for diverse design outcomes, including options like pu stone panel looks for different textures.

Key Takeaways:

- PVC UV Marble Sheets are cost-effective, waterproof, and durable alternatives to natural marble, made from PVC with a protective UV coating.

- They are ideal for bathrooms, kitchens, and other wet areas due to their moisture resistance and easy-to-clean surface.

- The UV coating provides a high gloss finish, enhances scratch resistance, and prevents the marble sheet pattern from fading.

- Benefits include aesthetic versatility (3D options available), ease of installation, low maintenance, and hygienic properties.

- Customization in design, size, and finish is often possible when dealing with a factory supplier.

- Installation is relatively straightforward and potentially DIY-friendly, but professional installation ensures the best results.

- Choosing a reliable supplier involves checking their factory status, experience, product quality (samples!), communication, and logistics capabilities.

- Always verify QC processes and demand authentic certifications (fire safety, environmental) from your supplier.

- PVC marble sheets are versatile and can be used for ceilings, furniture surfacing, and various decorative elements beyond just wall panels.

As Allen from Xihongbm, I hope this detailed guide provides valuable insights for buyers like Mark Wilson and anyone interested in using PVC UV marble sheets for their decoration projects. Feel free to explore our range of wall panels and marble sheets on our website.