CATEGORIES

Precision High Glossy 3mm PVC Marble Sheet PVC Film: The Ultimate Guide

Discover the elegance and practicality of PVC marble sheets and PVC film. This article delves into why these high glossy materials, often available in precise 3mm thicknesses, are transforming interior design. Whether you're a procurement officer like Mark Wilson, comparing options against natural marble, or an architect seeking versatile decorative solutions, read on to understand the benefits, applications, and key considerations when sourcing marble PVC film and sheets. Learn why this sheet product is a smart, stylish, and cost-effective choice for modern spaces.

1. What Exactly is a PVC Marble Sheet and Why is it Gaining Popularity?

A PVC marble sheet, sometimes referred to as a marble PVC panel or UV marble sheet, is a type of decorative wall panel made primarily from Polyvinyl Chloride (PVC) resin and calcium carbonate. Advanced printing and coating technologies are used to mimic the intricate patterns and natural beauty of marble. Often, a protective UV coating is applied to enhance durability and create a high glossy finish. The result is a lightweight, versatile, and visually stunning alternative to heavy, expensive real marble. We see buyers, particularly those like Mark looking for cost-effective solutions from regions like Shandong, increasingly turning to these PVC products.

The rising popularity stems from several factors. Firstly, the aesthetic appeal is undeniable; modern PVC marble sheets replicate the elegance of marble with remarkable precision. Secondly, they offer significant practical advantages over natural marble, including ease of installation, lower cost, and better resistance to moisture and stain issues. Thirdly, their versatility allows them to be used in a wide range of applications, from residential bathrooms and kitchens to large commercial spaces like hotels and shopping malls. This blend of beauty, practicality, and affordability makes PVC marble a compelling decoration material in today's market.

As a manufacturer with multiple production lines based in China, we've witnessed this surge firsthand. Our clients, including construction firms and interior designers across the USA, Europe, and Australia, appreciate the consistent quality and the ability to achieve a luxurious look without the traditional drawbacks of stone. The development of PVC film technology, specifically marble PVC film, further expands the possibilities, allowing for application on various surfaces beyond just walls. It's a sheet product that truly meets modern design demands.

2. How Does PVC Marble Sheet Compare to Natural Marble in Looks and Cost?

When comparing PVC marble sheet to natural marble, the visual difference is becoming increasingly subtle thanks to advanced manufacturing techniques. High-quality PVC marble sheets can replicate the veining, color variations, and depth of real marble with impressive accuracy. The high glossy finish available on many PVC options further enhances this resemblance, reflecting light similarly to polished stone. While a geologist might spot the difference up close, for most observers, a well-made marble PVC panel offers a remarkably convincing marble aesthetic.

The most significant difference lies in the cost. Natural marble is a premium material, expensive to quarry, transport, cut, and install. PVC marble sheets, being manufactured from PVC and calcium carbonate, are substantially more affordable – often costing a fraction of the price per square meter. This cost-effectiveness extends to installation as well; PVC panels are lighter and easier to handle, reducing labor time and costs. For businesses like Mark Wilson's, aiming to provide value to their clients, this price advantage is a major selling point, making the luxurious look of marble accessible for a wider range of projects and budgets. This makes marble PVC film and sheets a very attractive cost-effective solution.

Furthermore, consider the consistency. Natural marble slabs vary significantly, which can be part of their charm but also a challenge for large projects requiring uniformity. PVC marble sheets offer predictable patterns and colors, ensuring a consistent look across extensive installations. While natural marble possesses a unique geological history and inherent prestige, PVC marble provides a practical, affordable, and aesthetically pleasing alternative that meets the demands of modern construction and interior design. The availability of marble PVC film is available in various designs further enhances its appeal.

3. Is PVC Marble Sheet Truly Waterproof and Ideal for Wet Areas?

Yes, one of the standout features of PVC marble sheet is its excellent waterproof quality. Unlike natural marble or other materials like wood or MDF which can be porous or susceptible to water damage, PVC (Polyvinyl Chloride) is inherently resistant to moisture. The core material does not absorb water, preventing issues like swelling, warping, mold, or mildew growth. This makes PVC marble sheets an ideal choice for areas prone to dampness and humidity.

This inherent water resistance makes marble PVC panels perfect for applications in bathrooms, kitchens (especially as backsplashes), laundry rooms, basements, and even shower enclosures. The non-porous surface ensures that water simply sits on top and can be easily wiped away. Many PVC marble sheet products also feature interlocking or seamless joint systems, further minimizing potential water ingress points when installed correctly. This is a key advantage over traditional tile installations, which rely heavily on grout integrity to remain waterproof.

For procurement officers like Mark, sourcing materials for construction projects, this waterproof characteristic is a critical factor. It translates to longer product life, reduced maintenance concerns for the end-user, and suitability for a broader range of applications. We always emphasize this benefit, as it directly addresses common pain points associated with materials in wet environments. Using a PVC marble sheet or even a marble PVC film in these areas provides peace of mind and lasting performance, making it perfect for both residential and commercial projects requiring durability against moisture.

4. What Makes High Glossy UV PVC Marble Sheets So Appealing for Interior Decoration?

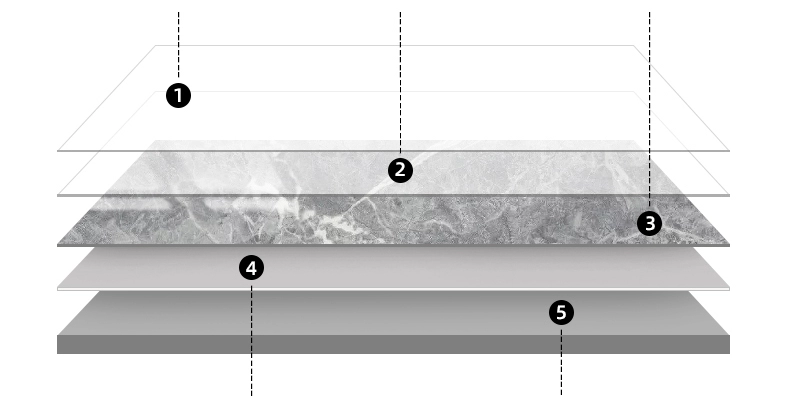

The appeal of high glossy UV PVC marble sheets in interior decoration lies in their ability to combine the luxurious aesthetic of polished marble with the durability and practicality of modern materials. The high glossy finish creates a reflective surface that bounces light around the room, making spaces feel brighter, larger, and more opulent. This effect is highly sought after in contemporary interior design, adding a touch of luxury to walls, ceiling areas, and feature panels.

The "UV" part refers to an ultraviolet-cured coating applied to the PVC marble sheet. This UV coating serves multiple purposes. Firstly, it provides a hard, protective layer that significantly enhances scratch resistance and overall durability, crucial for maintaining the pristine look, especially in high-traffic areas. Secondly, it seals the printed marble pattern, protecting it from fading caused by sunlight exposure. Thirdly, it contributes significantly to the deep, lustrous high glossy appearance that mimics polished stone so effectively. This combination makes UV marble sheets both beautiful and resilient.

For designers and architects specifying materials, PVC UV marble sheets offer a way to achieve a high-end look without the associated costs and installation challenges of natural marble. The wide variety of available patterns, from classic Carrara to dramatic black marble looks, allows for creative freedom. These decorative films or panels can instantly elevate the visual appeal of a space, whether it's a hotel lobby, a modern office, or a stylish home kitchen. The result is a sophisticated interior decoration solution that is both visually stunning and built to last.

5. How Easy is the Installation Process for PVC Marble Panels?

Installation is another area where PVC marble panels significantly outperform natural marble. Their lightweight nature is a primary advantage. Unlike heavy stone slabs that require specialized equipment and significant manpower to lift and position, PVC marble sheets can typically be handled and installed by one or two people. This dramatically simplifies logistics and reduces labor costs associated with the installation process.

The installation methods themselves are generally straightforward, often making it a suitable material for DIY enthusiasts as well as professionals. Common methods include:

- Adhesive Application: Applying a suitable construction adhesive to the back of the panel and pressing it firmly onto a clean, prepared wall surface.

- Mechanical Fastening: Some systems may involve screwing or nailing the panels directly to studs or a substrate, often using interlocking edges to hide fasteners.

- Interlocking Systems: Many PVC marble wall panel designs feature tongue-and-groove or similar interlocking edges, creating a seamless look and simplifying alignment during installation.

Preparation of the surface is key – it should be clean, dry, and relatively flat. However, PVC panels can often be installed over existing surfaces like tiles or drywall, minimizing demolition work during renovation projects. Cutting the PVC marble sheets to size is also relatively easy, typically achievable with standard woodworking tools like a circular saw or even a utility knife for thinner sheet options. This ease of cutting and handling makes fitting panels around obstacles like outlets or windows much simpler than working with stone, ensuring installation a breeze.

6. Are PVC Marble Sheets Durable Enough for High-Traffic Areas? (Exploring Durability & Scratch Resistance)

The durability of PVC marble sheets is a common question, especially for applications in busy environments. Generally, high-quality PVC marble sheets, particularly those with a robust UV coating, offer good durability and are suitable for many high-traffic commercial and residential areas. The PVC core provides inherent resistance to impacts, moisture, and stains, while the protective top layer is key to resisting daily wear and tear.

Scratch resistance is often enhanced by the UV coating. This hard layer helps protect the printed marble pattern underneath from minor scuffs, abrasions, and everyday impacts. While not completely impervious (no surface truly is), a good quality UV marble sheet will hold up well against the rigors of normal use. It's important to note that the level of scratch resistance can vary depending on the quality of the PVC, the thickness of the sheet, and specifically the quality and thickness of the UV protective coating. As manufacturers, we often advise clients on the specific grade suitable for their intended application to ensure longevity.

Compared to some alternatives like painted drywall, PVC marble sheets offer superior resistance to dents, chips, and stains. While natural marble is hard, it can be prone to chipping, staining, and etching, especially from acidic substances. PVC marble, being non-porous and chemically resistant, generally handles spills and potential stain agents much better. For areas demanding both aesthetic appeal and resilience, durable PVC marble panels present a balanced and practical solution. Proper care, like avoiding abrasive cleaners, will further extend their lifespan.

7. Can PVC Marble Sheets Be Customized for Specific Design Needs?

Yes, customization is a significant advantage when working with PVC marble sheets and marble PVC film. As manufacturers, we understand that architects, designers, and developers often require specific aesthetics to match their project vision. While there's a vast wide range of standard marble patterns and colors available – mimicking everything from classic white marbles to bold, dark stones – the potential for customization offers even greater flexibility.

Options to customize can include:

- Custom Patterns: Depending on the manufacturer's capabilities and order volume, it may be possible to create custom designs or replicate specific marble patterns not found in standard collections. This often involves advanced digital printing directly onto the PVC sheet or PVC film before the protective coating is applied.

- Specific Sizes: While standard sizes like 1220x2440mm (4x8 ft) are common, PVC marble sheets can often be produced or cut to custom dimensions to minimize waste and suit specific project requirements, especially for large B2B orders. The 3mm thickness is popular, but variations might be possible.

- Finish Variations: Beyond the popular high glossy finish, options like matte or textured finishes might be available or developed for specific projects, offering different tactile and visual effects.

- PVC Film Lamination: Marble PVC film itself offers extensive customization, as it can be applied to various substrates beyond standard wall panels, such as furniture boards, doors, and countertops, allowing for a coordinated marble theme across different elements of an interior decoration project.

Discussing customization possibilities early in the procurement process is crucial. For buyers like Mark Wilson, understanding the minimum order quantities, lead times, and potential costs associated with custom orders is essential. However, the ability to tailor the marble PVC product allows for unique and highly specific design outcomes, making it a preferred choice for projects demanding a distinct aesthetic identity. Explore our Hot Stamping Foil Marble Sheet options for versatile pattern choices.

8. Beyond Walls: What Are Other Versatile Applications for Marble PVC Film? (Ceilings, Furniture)

While PVC marble sheets are commonly used as wall panel solutions, the underlying technology, particularly marble PVC film, unlocks a much broader range of applications. This highly versatile decorative film is essentially a thin layer of PVC printed with a marble pattern, often with an adhesive backing or designed for lamination onto other substrates. This flexibility allows the elegance of marble to be incorporated into various elements of interior design.

Common applications beyond walls include:

- Ceilings: Applying marble PVC film or lightweight PVC marble panels to ceiling areas can create dramatic focal points, especially in commercial spaces like hotel lobbies or restaurants, adding a touch of elegance.

- Furniture Surfacing: Marble PVC film is widely used in the furniture industry to cover surfaces like tabletops, cabinet doors, shelves, and countertops. This provides a luxurious look at a lower cost and weight compared to solid stone, and offers better durability and stain resistance than many wood veneers. Check out how versatile our PVC Film Marble Sheet can be.

- Doors and Columns: Wrapping doors or columns with marble PVC film can integrate these architectural elements seamlessly into a marble-themed design scheme.

- Retail Displays and Fixtures: The film's ease of application and visual impact make it suitable for creating eye-catching retail displays, kiosks, and fixtures.

- Elevator Interiors: PVC marble panels or films offer a lightweight and stylish way to upgrade elevator cabins.

The use of marble PVC film allows for design cohesion across different surfaces and objects within a space. It's a cost-effective solution for achieving a high-end aesthetic on various surfaces where using heavy PVC marble sheet or real marble would be impractical or too expensive. Its adaptability makes marble PVC film boasts significant potential for creative interior decoration, enabling designers to achieve a sophisticated and coordinated marble effect throughout an environment. The film is designed for ease of use in many scenarios.

9. Maintaining the Shine: How Simple is Cleaning and Upkeep for PVC Marble Surfaces?

One of the significant practical benefits of PVC marble sheets and surfaces covered with marble PVC film is their ease of maintenance. The non-porous nature of PVC combined with the smooth, often high glossy or UV-coated surface, makes cleaning remarkably simple. Unlike natural marble, which can be sensitive to acidic cleaners and prone to staining, PVC marble surfaces are generally very resistant to common household spills and dirt.

For routine cleaning, all that's typically required is a soft damp cloth or sponge. Mild soap and water can be used for more stubborn grime. You can simply wipe the surface clean without worrying about damaging the material or the finish. This hassle-free maintenance makes PVC marble ideal for busy households and commercial environments where cleanliness and hygiene are important, but extensive upkeep time is undesirable. It truly is easy to clean.

It's generally recommended to avoid abrasive cleaners, scouring pads, or harsh solvents (like acetone), as these could potentially dull the glossy finish or scratch the surface over time. However, compared to the specific sealing and cleaning requirements of natural marble, PVC marble offers a far more forgiving and low-maintenance alternative. This ease of care contributes to its growing popularity, ensuring the surface retains its attractive appearance with minimal effort, making it easy to keep spaces looking fresh and stylish. Consider our easy-to-maintain WPC Wall Panel options as well for durable surfaces.

10. Choosing the Right Supplier: Key Considerations for Quality PVC Marble Sheet Procurement

For buyers like Mark Wilson, sourcing PVC marble sheets or marble PVC film from overseas suppliers like those in China requires careful consideration to ensure quality, reliability, and smooth transactions. Choosing the right supplier is paramount to avoiding common pain points like poor communication, shipment delays, and issues with product quality or certifications. As a factory owner myself (Allen), I understand these concerns well.

Key factors to consider when selecting a supplier include:

- Manufacturing Capabilities: Does the supplier have their own factory (like our 7 production lines) or are they just a trading company? Direct manufacturers often offer better quality control, potential for customization, and more competitive pricing. Verify their production capacity and technology, especially for UV coating and precision printing.

- Quality Control Processes: Inquire about their quality inspection procedures. Do they test for scratch resistance, color consistency, thickness (3mm precision), adhesion (for PVC film), and waterproof integrity? Requesting samples for evaluation is crucial.

- Certifications: Ask for relevant certifications upfront – fire safety ratings (e.g., ASTM E84 for the US market), environmental certifications (eco-friendly materials, low VOCs), and quality management systems (like ISO 9001). Be cautious and verify the authenticity of certificates if possible, addressing Mark's concern about fraud. Reliable suppliers are transparent about their compliance.

- Communication and Support: Evaluate the responsiveness and clarity of communication from the sales team. Efficient communication is vital for resolving issues and managing orders effectively, a key pain point Mark experiences. Look for suppliers with experience serving your market (e.g., USA, Europe).

- Logistics and Lead Times: Discuss shipping options, estimated lead times, and packaging methods to prevent damage during transit. Reliable suppliers provide realistic timelines and work to meet project deadlines. Understand payment terms clearly. Platforms like Alibaba.com can offer trade assurance, but direct vetting is still important.

- Product Range and Customization: Assess if their product range (PVC marble sheet, PVC decorative film, wall panel PVC, 3d wall panels) meets your needs and if they offer the required customization options.

Building a relationship with a trustworthy manufacturer is key to a successful B2B partnership. Look for transparency, proven experience, and a commitment to quality. Taking the time to vet suppliers thoroughly can prevent costly mistakes and ensure you receive high-quality PVC marble products that meet your clients' expectations. Feel free to send us an inquiry regarding your specific needs for PVC marble sheet PVC film or other decorative panels like our XHA01 PS Wall Panel.

Key Takeaways:

- PVC Marble Sheets & Films offer a visually stunning, cost-effective, and practical alternative to natural marble.

- They excel in waterproof performance, making them ideal for kitchens, bathrooms, and other damp areas.

- High glossy UV coatings enhance aesthetic appeal (brightness, luxury) and provide crucial durability and scratch resistance.

- Installation is significantly easier and cheaper than stone due to the lightweight nature of PVC and straightforward methods (adhesive, interlocking).

- These materials are highly versatile, usable on walls, ceilings, furniture, doors, and more, especially marble PVC film.

- Maintenance is simple – typically requiring just a damp cloth, making them easy to clean.

- Customization options (patterns, sizes, finishes) allow for tailored interior design solutions.

- Choosing a reliable manufacturer with proven quality control, certifications, and good communication is vital for successful B2B procurement.