CATEGORIES

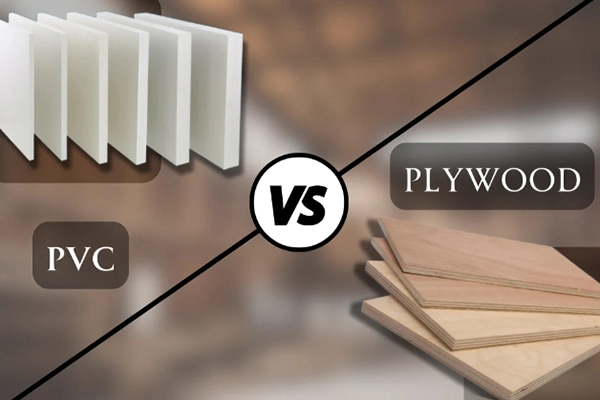

Plywood vs. PVC: Which Sheet Material is More Popular for Interior Building Projects?

This article explores the differences between plywood and PVC sheets and boards, two common materials used in interior building and construction. We will delve into their properties, applications, pros and cons, and ultimately, which one is gaining popularity in modern projects. Reading this article will help construction companies, interior designers, architects, and home improvement retailers make informed decisions when selecting materials for their projects.

What is Plywood and What are its Main Characteristics?

Plywood is an engineered wood product made by gluing together thin layers of wood veneer, called plies. These plies are stacked with the grain of each layer rotated up to 90 degrees to its adjacent layer. This cross-graining gives plywood its strength and dimensional stability, making it less prone to warping or cracking compared to solid wood.

Plywood is used in a variety of applications, including:

- Structural components in building, such as walls, floors, and roofs.

- Furniture making.

- Cabinetry and shelving.

- Door manufacturing.

Some key characteristics of plywood: - Strength: The cross-grained construction gives plywood excellent strength in both directions.

- Durability: Plywood can be very durable, especially when treated for moisture resistance.

- Versatility: Available in a wide range of thicknesses and grades, suitable for various applications.

- Workability: Plywood is relatively easy to cut, shape, and fasten with nails, screws, or glue.

*Can emit small amount of formaldehydeWhat is PVC and How Does it Differ from Plywood?

PVC, or polyvinyl chloride, is a synthetic plastic polymer. It is a thermoplastic material, meaning it can be repeatedly softened by heating and hardened by cooling. In the context of building materials, PVC is commonly found in the form of rigid sheets or boards, often referred to as PVC foam board or PVC foam sheet.

PVC is known for use in construction and decorative needs.

High-quality PVC offers water and chemical resistance.

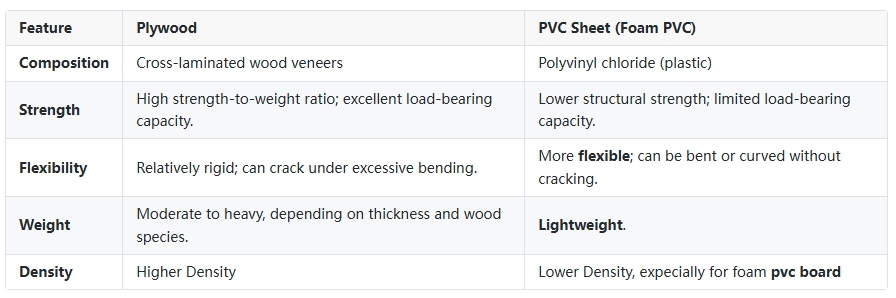

The primary difference between PVC and plywood lies in their composition. Plywood is derived from wood, while PVC is a synthetic plastic made from petroleum. This fundamental difference leads to variations in their properties and applications. PVC does not contain wood fiber, making pvc sheets naturally resistant to moisture and rot, a key advantage over plywood.What are the Structural Differences Between Plywood and PVC Sheets?

The structural difference between PVC and plywood is significant. Plywood derives its strength from the cross-laminated wood veneers, offering a high strength-to-weight ratio. It can bear considerable loads and is often used in structural applications where load-bearing capacity is essential.

PVC sheets, particularly foam PVC, are considerably lightweight and have lower structural strength compared to plywood. While rigid PVC can be used for some structural purposes, it's not as strong as plywood in terms of load-bearing. However, PVC's inherent flexibility can be an advantage in certain applications where bending or curving is required.

Here's a table summarizing the structural differences:

Where is Plywood Most Suitable for Application?

Plywood is used in a broad scope of building projects. Plywood is most suitable for applications where structural integrity and strength are paramount. These include:

- Structural Framing: Plywood is a staple in wall sheathing, roof decking, and subflooring, providing a solid and stable base for the rest of the construction.

- Cabinetry and Shelving: Its strength and ability to hold screws and nails well make plywood ideal for building durable cabinets, shelves, and other storage solutions.

- Furniture Making: Plywood offers a cost-effective and stable alternative to solid wood for creating furniture pieces.

- Exterior Applications (Treated Plywood): Certain types of plywood are treated to resist moisture and rot, making them suitable for exterior use, such as siding or outdoor furniture. However, even treated plywood may not endure excessive moisture as well as PVC.

- Concrete formwork.

What are the Best Applications for PVC Sheets in Interior Design?

PVC sheets offer a wide range of applications, particularly in interior design, where their moisture resistance, versatility, and aesthetic appeal are highly valued. Some key applications include:

- Wall Paneling: PVC wall panels are a popular choice for bathrooms, kitchens, and other areas prone to moisture. They are waterproof, easy to clean, and come in a variety of designs and textures, including those that mimic wood or marble (like our PVC marble sheets).

- Ceiling Tiles: PVC ceiling tiles are lightweight, easy to install, and provide excellent moisture resistance.

- Decorative Elements: PVC can be easily molded and shaped, making it ideal for creating intricate decorative moldings, trims, and other design features.

- Signage and Displays: PVC foam board is commonly used for signage, display boards, and exhibition stands due to its lightweight nature and smooth surface, which is perfect for printing.

- Kitchen Backsplash.

Plywood vs. PVC: A Detailed Comparison of Durability and Longevity

Durability and longevity are crucial factors when choosing building materials.

- Plywood: When properly maintained and protected from moisture, plywood can be very durable. However, prolonged exposure to water can lead to warping, swelling, and delamination (separation of the layers). Exterior-grade plywood is treated to resist moisture, but it's still not as inherently waterproof as PVC.

- PVC: PVC is inherently waterproof and resistant to rot, mold, and mildew. This makes it an exceptionally durable option for areas exposed to high humidity or direct contact with water. PVC also resists many chemicals and is less susceptible to damage from pests.

In summary, while plywood can be durable, PVC generally offers superior durability and longevity, especially in moist or wet environments. PVC also has excellent weathering resistance.Cost Analysis: Plywood vs. PVC - Which is More Economical?

The cost of plywood and PVC can vary depending on several factors, including grade, thickness, size, and supplier.

- Plywood: Generally, plywood is considered a cost-effective material, especially for structural applications. However, higher grades of plywood, such as marine-grade or hardwood plywood, can be more expensive.

- PVC: The cost of PVC sheets can vary widely. Foam PVC board is generally less expensive than solid PVC sheet. PVC marble sheets, designed to mimic the look of marble, can be more cost-effective than natural marble while still providing a luxury aesthetic.

For structural applications where strength is the primary concern, plywood often provides a lower cost per unit of strength. However, for applications where moisture resistance and longevity are paramount, the higher initial cost of PVC may be offset by its longer lifespan and lower maintenance requirements.

How Easy is it to Work with Plywood and PVC? (Installation and Maintenance)

- Plywood:

- Installation: Plywood is relatively easy to work with using standard woodworking tools. It can be cut with saws, drilled, and fastened with nails, screws, or glue. However, cutting plywood can sometimes produce splinters, and care must be taken to avoid damaging the veneer layers. Requires power tools.

- Maintenance: Plywood generally requires some form of finish, such as paint, varnish, or sealant, to protect it from moisture and wear. Regular cleaning and occasional re-finishing may be needed to maintain its appearance and longevity.

- PVC:

- Installation: PVC sheets, especially foam PVC, are lightweight and easy to handle. They can be cut with utility knives, saws, or routers. PVC can be glued using PVC cement or other specialized adhesives. Many PVC wall panels are designed for easy installation, often featuring interlocking edges or tongue-and-groove systems. Check out our easy-to-install WPC wall panels for an example.

- Maintenance: PVC is exceptionally low maintenance. It's waterproof, so it doesn't require sealing or painting. Cleaning is usually as simple as wiping with a damp cloth. PVC is also resistant to staining and fading.

Environmental Impact: Is Plywood or PVC a More Eco-Friendly Choice?

- Plywood: The environmental impact of plywood depends on the sourcing of the wood and the manufacturing process. Plywood made from sustainably harvested wood, certified by organizations like the Forest Stewardship Council (FSC), is a more eco-friendly option. However, some plywood may contain formaldehyde-based adhesives, which can release volatile organic compounds (VOCs) into the air.

- PVC: PVC is a petroleum-based product, and its production involves the use of chlorine, which can have negative environmental impacts. However, PVC is highly durable and long-lasting, which can reduce the need for frequent replacement. Additionally, some manufacturers are now producing PVC from recycled materials, and PVC itself is recyclable, reducing its overall environmental footprint. Our company, Xihong, is committed to using recyclable materials in our PVC products.

Neither plywood nor PVC is a perfectly "green" material. However, choosing plywood from sustainable sources or PVC products made with recycled content can help minimize their environmental impact.What Future Trends are Emerging for Plywood and PVC in Building?

- Plywood:

- Increased Use of Sustainable Wood: There's a growing demand for plywood made from sustainably sourced wood, driven by consumer awareness and stricter environmental regulations.

- Improved Adhesives: Manufacturers are developing plywood with low-VOC or formaldehyde-free adhesives to improve indoor air quality.

- Engineered Wood Products: Cross-laminated timber (CLT) and other engineered wood products are gaining popularity as sustainable alternatives to concrete and steel in large-scale construction.

- PVC:

- Recycled PVC: The use of recycled PVC in building materials is increasing, reducing the demand for virgin plastic and minimizing waste.

- Enhanced Performance: Manufacturers are developing PVC products with improved properties, such as increased UV resistance, fire retardancy, and impact resistance. For example, our fire-retardant WPC siding offers superior safety.

- Aesthetic Advancements: PVC products are becoming increasingly sophisticated in terms of aesthetics, with a wider range of colors, textures, and finishes available, including realistic wood grain and marble effects.

Addressing Common Concerns When Purchasing from Overseas Suppliers

Mark Wilson, and procurement officers like him, often face challenges when sourcing building materials from overseas suppliers like those in China and Vietnam. Addressing these concerns directly is crucial for building trust and fostering long-term business relationships.

- Quality Inspection: This is a primary concern. How can I be sure the product meets my standards?

- Solution: Xihong, as a factory with 7 production lines, implements rigorous quality control measures throughout the manufacturing process. We welcome third-party inspections and can provide detailed quality reports. We can also send samples for pre-shipment approval. We are also very familiar with different country’s product standards.

- Certifications (Fire Safety, Environmental): Are the certifications genuine and valid?

- Solution: Xihong provides all necessary certifications, including fire safety ratings and environmental certifications, complying with international standards (USA, North America, Europe, Australia). We are transparent about our certification processes and can provide documentation upon request.

- Logistics and Shipment Delays: Will my shipment arrive on time, and what happens if there are delays?

- Solution: Xihong has extensive experience exporting to the USA, North America, Europe, and Australia. We work with reputable logistics partners to ensure timely delivery. We provide regular shipment updates and proactively address any potential delays. We also offer flexible shipping options to meet specific project timelines.

- Payment Methods: What are the payment options, and are they secure?

- Solution: Xihong offers secure payment methods, including T/T (Telegraphic Transfer) and L/C (Letter of Credit). We are flexible and willing to discuss payment terms that work for both parties.

- Inefficient Communication: Will I be able to communicate effectively with the sales representatives?

- Solution: My name is Allen, and I, along with my team, am committed to clear and prompt communication. We understand the importance of responsiveness and are available to answer questions and address concerns throughout the entire process. We value clear and direct communication, mirroring the decisive personality of clients like Mark.

- Certificate fraud: How to tell if a certificate is valid?

- Solution: Xihong only provides genuine, verifiable certificates. We can explain how to check for and verify validity if needed.

Summary of Key Points

- Plywood and PVC are distinct building materials with unique properties and applications.

- Plywood is a strong, versatile wood-based product suitable for structural applications.

- PVC is a waterproof, durable, and low-maintenance plastic material ideal for areas exposed to moisture.

- PVC generally offers superior moisture resistance and longevity compared to plywood.

- Plywood can be more cost-effective for structural applications, while PVC may be a better long-term investment for areas prone to moisture.

- Both plywood and PVC have environmental considerations, but choosing sustainable options can minimize their impact.

- Future trends point towards increased use of sustainable materials and enhanced performance for both plywood and PVC.

- When purchasing product from oversea, make sure to verify certificates, quality and communicate efficiently.