CATEGORIES

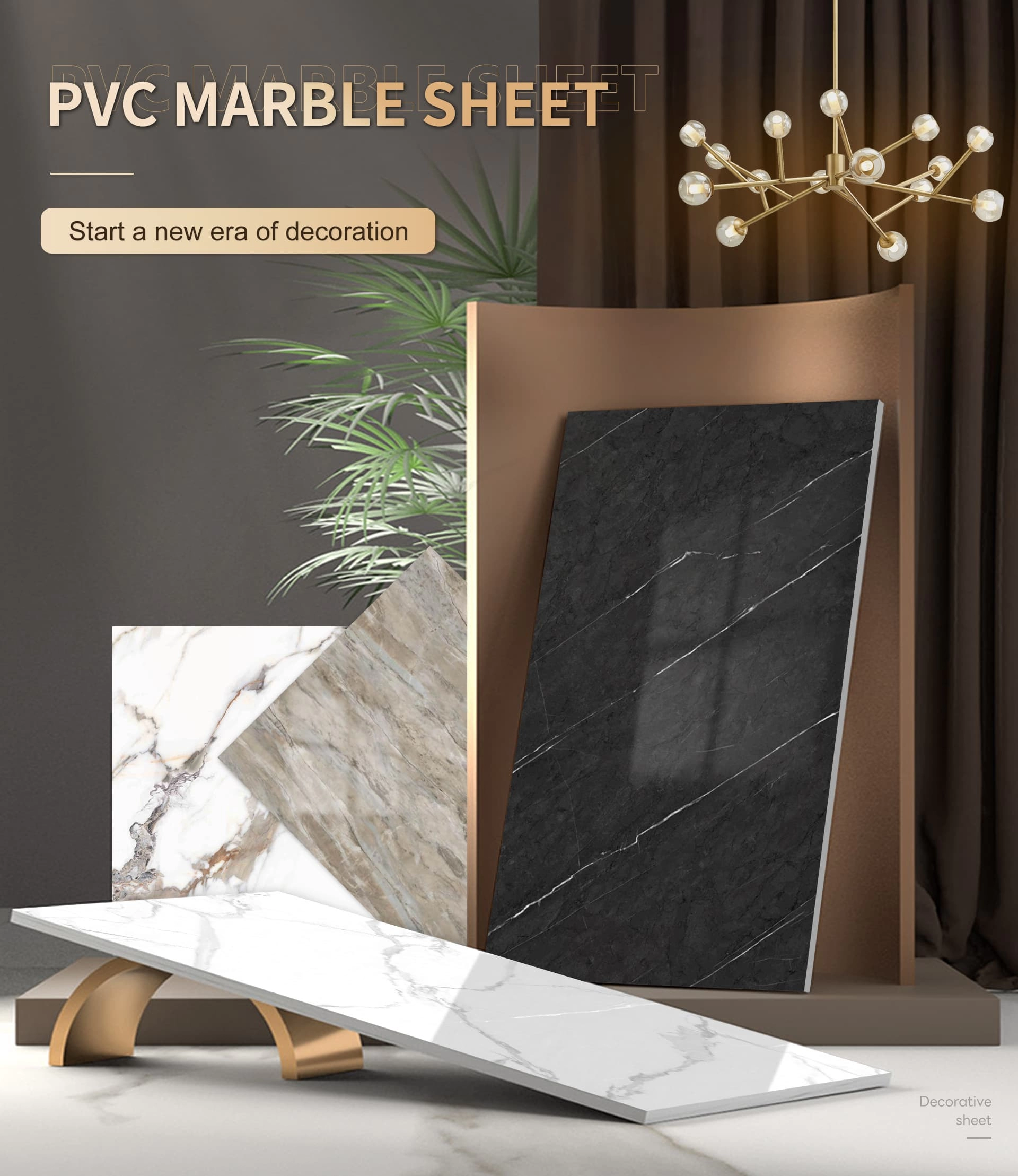

High Glossy 3D UV Coated PVC Marble Sheet: Revolutionizing Decorative Wall Panels

Are you looking to elevate your interior spaces with the timeless elegance of marble without the hefty price tag and installation challenges? This article dives deep into the world of high glossy 3D UV coated PVC marble sheets, exploring their features, benefits, and why they are becoming the go-to decorative wall panel solution for businesses worldwide. Whether you're a construction company owner, an interior designer, or a home improvement retailer, understanding the potential of these innovative materials is crucial for staying ahead in today's market.

What is a UV Marble Sheet and Why is it a Popular Decorative Material?

A marble sheet, in its essence, is a decorative panel designed to replicate the luxurious appearance of natural marble. However, instead of being quarried from stone, these sheets are typically made from pvc. The popularity of uv marble sheets as a decorative material stems from their ability to offer a sophisticated, high-end look at a fraction of the cost of real marble. These sheets are manufactured through a high temperature heating extrusion production process. Their versatility makes them used in many different applications, from residential to commercial spaces. The key advantage lies in their blend of aesthetics and practicality. For example, consider a bustling retail store aiming for an elegant look – uv marble sheets are commonly used in such environments due to their durability and ease of maintenance.

Furthermore, the integration of uv panel technology enhances these sheets significantly. This involves coating the pvc marble sheet with a top layer with ultraviolet light. This process of curing or hardening the top layer makes the marble sheet more resistant to scratches, moisture, and fading. This robust finish ensures that the decorative panels not only look good but also last longer and less likely to show wear and tear. This combination of affordability, durability, and aesthetic appeal makes uv marble sheets an increasingly sought-after solution in the world of interior decoration.

High Glossy 3D UV Coating: How Does this Technology Enhance PVC Marble Sheets?

The term "high glossy 3d" in relation to uv coated pvc sheet refers to the specific treatment applied to the surface of the sheet. The uv coated layer is not just a protective shield; it also significantly enhances the visual appeal. The glossy finish creates a smooth, reflective surface that mimics the polished sheen of genuine marble, adding a touch of luxury to any space. Moreover, the "3d printing" aspect often refers to the advanced printing techniques used to create realistic marble patterns and textures on the pvc surface before the curing or hardening the top with top layer with ultraviolet. This 3d printing process allows for intricate veining and color variations, making the imitation marble appear incredibly similar to real marble.

The application of advanced uv printing technology ensures that the printed design is not only visually striking but also incredibly durable. The process of curing or hardening creates a hard, non-porous surface that is waterproof and resistant to stains, scratches, and fading. This is a significant advantage over natural marble, which can be porous and requires regular sealing to maintain its beauty. This easy to clean nature of high glossy 3d uv marble makes them ideal for areas prone to moisture or spills, such as bathrooms and kitchens. For someone like Mark Wilson, focusing on quality and longevity, this enhanced durability is a major selling point, ensuring the products he supplies to his clients will maintain their aesthetic appeal for years to come.

Where Can High Glossy 3D PVC Marble Sheets Be Used? Exploring Versatile Applications.

The versatility of marble sheet panels is one of their key selling points. They are commonly used to cover the inside of walls in a wide range of settings. In residential spaces, they can transform living rooms, bedrooms, and bathrooms, adding a touch of sophistication and elegance. Imagine marble-themed elements in the interior of a modern home – uv marble sheets are commonly used to create feature walls or elegant bathroom surrounds. Their waterproof nature makes them especially suitable for kitchens and bathrooms, helping to keep the walls dry and preventing moisture damage.

Beyond homes, pvc wall panels are extensively used in commercial spaces. Retail stores, hotels, restaurants, and offices utilize these panels to create visually appealing and easy-to-maintain environments. Their ability to mimic the luxurious look of marble makes them perfect for creating a high-end ambiance without the cost and logistical challenges of using natural marble. They can be used for wall cladding, counter fronts, and even to cover ceilings in interior design projects. The easy to install nature of these sheets also means less disruption during installation, a crucial factor for businesses looking to minimize downtime. Even in public spaces like schools and hospitals, the easy to clean and maintain properties of uv marble sheets are commonly appreciated, helping to maintain hygiene and aesthetics.

Why Choose UV Marble Sheets Over Natural Marble for Your Interior Design Project?

While natural marble is undeniably beautiful, uv marble sheets offer several practical advantages that make them a compelling alternative, particularly for B2B applications. The most significant advantage is cost. The cost of real marble can be substantial, encompassing not only the material itself but also the specialized labor required for installation. Uv marble sheets, on the other hand, are significantly cheaper than real marble, making them a more accessible option for budget-conscious projects. This is a critical factor for procurement officers like Mark Wilson who are quality-sensitive but also seeks competitive pricing.

Beyond cost, installation is another key differentiator. Natural marble slabs are heavy and require skilled stonemasons for precise cutting and installation. This process can be time-consuming and expensive. Pvc marble wall panels are much lighter and easier to install, often requiring just basic tools and adhesive. This reducing installation time and costs significantly. Furthermore, uv marble sheets are commonly manufactured in consistent sizes and thicknesses, ensuring a uniform and predictable finish, which can sometimes be a challenge with the natural variations found in natural marble. Durability and maintenance are also advantages. As mentioned, the uv coated surface is resistant to scratches, stains, and moisture, requiring minimal upkeep compared to the regular sealing and careful cleaning needed for natural marble. For interior design project managers and construction companies, these practical benefits make uv marble a smart and efficient choice.

Easy Installation and Low Maintenance: Key Benefits of PVC Marble Wall Panels.

The easy to install nature of pvc wall panels is a major draw for many users. Unlike natural marble, which demands specialized skills and equipment for installation, pvc marble sheets can be installed relatively quickly and easily. The sheets are lightweight and can be cut on-site with standard tools, reducing the need for pre-fabrication and minimizing waste. Typically, the installation involves applying adhesive to the back of the sheet and pressing it onto the prepared wall surface. This straightforward process significantly reduces labor costs and installation time, making it an attractive option for projects with tight deadlines or budget constraints. For construction companies, this translates to faster project completion and lower overall costs.

Coupled with easy to install, the easy to clean and maintain aspect of these panels is a significant benefit. The non-porous uv coated surface resists stains, moisture, and mildew, making cleaning a simple task. A quick wipe with a damp cloth is usually all that's needed to keep the panels looking pristine. This low-maintenance feature is particularly appealing for commercial spaces and high-traffic areas where durability and ease of cleaning are paramount. This ease of maintenance also contributes to the long-term cost-effectiveness of pvc marble sheets, as it reduces the need for frequent repairs or replacements. This aligns perfectly with Mark Wilson's goal of providing his clients with durable and cost-effective solutions.

What Makes UV Marble Sheets a Cost-Effective and Durable Decorative Material?

The cost-effectiveness of uv marble sheets extends beyond the initial purchase price. As previously discussed, the lower installation costs due to the ease of handling and installation contribute significantly to the overall savings. Furthermore, the durability of these sheets means they have a longer lifespan compared to some other decorative sheets, reducing the frequency of replacements and saving money in the long run. The resistance to scratches, stains, and moisture ensures that the panels maintain their aesthetic appeal for years, reducing the need for costly repairs or renovations.

Durability is a cornerstone of the appeal of uv marble. The uv coated layer provides a robust protective barrier, making the marble sheet resistant to everyday wear and tear. This is particularly important in high-traffic areas or spaces where the walls might be subject to bumps and scrapes. The waterproof nature of the panels also makes them ideal for damp environments, preventing issues like mold and mildew growth that can damage walls and require expensive remediation. This combination of longevity and resistance to damage makes uv marble sheets a smart investment for both residential and commercial applications. The fact that they are less likely to scratch than many other wall coverings further enhances their long-term value.

Are UV Marble Sheets an Environmentally Conscious Choice for Wall Panels?

In today's market, environmental protection is a growing concern for businesses and consumers alike. Uv marble sheets can be a more environmental protection choice compared to natural marble due to several factors. The extraction of natural marble can have a significant impact on the environment, involving quarrying, which can lead to habitat destruction and landscape alteration. Manufacturing pvc marble sheets, while still an industrial process, can have a smaller environmental footprint, especially if the manufacturer utilizes recyclable materials.

Furthermore, the longevity of uv marble sheets contributes to their environmental friendliness. Because they last longer and less likely require replacement, the demand for new materials and the associated environmental impact of production and transportation are reduced. Choosing durable and long-lasting materials is a key aspect of sustainable building practices. While pvc itself is a synthetic material, responsible manufacturing processes and the use of recycled content can mitigate some of the environmental concerns. For businesses aiming to align with sustainability goals, considering the lifecycle of building materials like wall panel options is crucial. By choosing durable and long-lasting options, we can collectively reduce our damage to the environment.

How Does 3D Printing Technology Elevate the Look of UV Marble Sheets?

The integration of "3d printing" technology in the production of uv marble sheets has revolutionized their aesthetic appeal. Traditional methods of creating imitation marble patterns often resulted in flat, repetitive designs. However, 3d printing allows for the creation of incredibly realistic and varied marble veining and patterns. This technology enables manufacturers to replicate the intricate details and natural variations found in genuine marble, making the imitation marble virtually indistinguishable from the real thing to the untrained eye.

This advanced printing process allows for a wider variety of colors and patterns, giving designers and architects greater creative freedom. Instead of being limited to a few standard marble designs, they can choose from a vast array of options, from classic Carrara white to dramatic black marble with gold veining. The "3d printing" also adds depth and texture to the surface of the sheet, further enhancing its realistic appearance. This level of detail elevates the overall look of the pvc marble sheet, making it a truly compelling alternative to natural marble for those seeking a luxurious and sophisticated finish. This level of realism is a significant factor in why these sheets are popular for high-end interior design project applications.

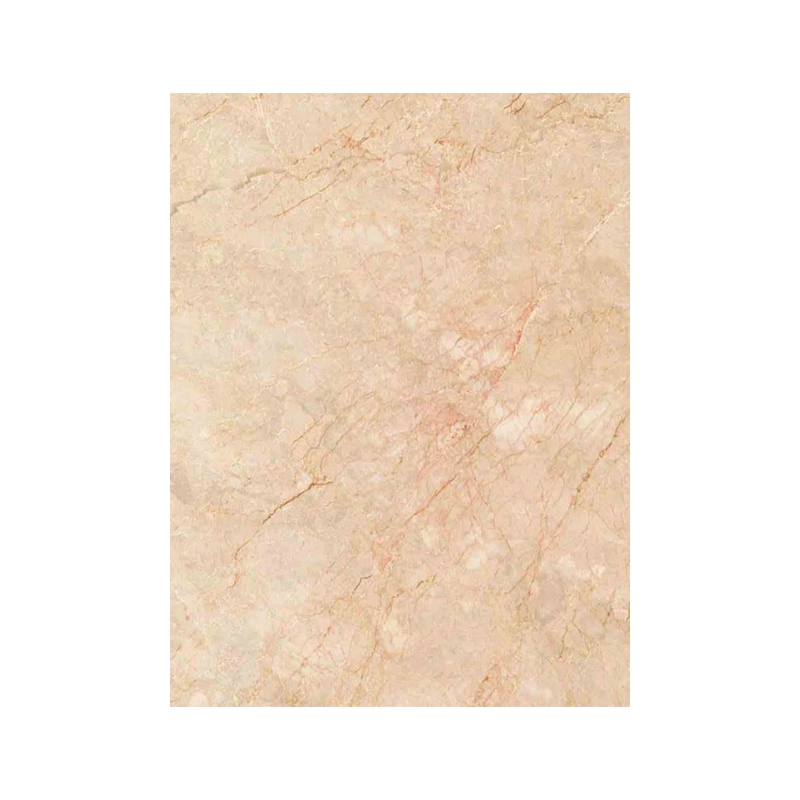

What Variety of Colors and Veining Options are Available in UV Marble Sheets?

The beauty of uv marble sheets lies not only in their practicality but also in the incredible variety of colors and veining patterns available. Manufacturers like us at our factory in China, with 7 production lines, can produce pvc sheets in a vast spectrum of hues, from the classic whites and creams of traditional marble to bolder colors like blues, greens, and even metallic finishes. This allows for seamless integration into diverse interior design project aesthetics.

The veining, the intricate lines and patterns that define marble, is another area where uv marble sheets excel. Advanced printing technologies allow for the replication of various marble types, from the subtle, feathery veins of Calacatta marble to the bolder, more dramatic veining of Nero Marquina. This extensive selection ensures that designers can find the perfect marble sheet to complement their vision, whether they are aiming for a classic, contemporary, or avant-garde look. This vast selection surpasses the limitations often encountered when sourcing natural marble, where color and veining options can be restricted by quarry availability. For customers like Mark Wilson in the USA, this variety of colors and patterns makes these sheets highly marketable to a wide range of clients.

Choosing the Right UV Marble Sheet Supplier: What Factors Should You Consider?

Selecting the right supplier for your uv marble sheet needs is crucial for ensuring quality, reliability, and competitive pricing. As a panel manufacturer and factory based in China, linyi aiwei international trade co (that's us, operating under the brand you see in the file) has extensive experience in producing high-quality pvc marble sheets and wpc wall panels. When choosing a supplier, consider factors such as production capacity, quality control measures, certifications, and export experience. For instance, our identity as a factory with 7 production lines assures you of our ability to handle large orders and maintain consistent product quality.

Certifications are also vital. Look for suppliers who can provide certifications related to fire safety ratings and environmental protection. This is a key concern when purchasing for clients like Mark Wilson. Experience in exporting to your target markets, such as the USA, North America, Europe, Australia, is another important factor. This indicates familiarity with international standards, logistics, and documentation requirements. Communication is also key. Efficient communication with the supplier's sales representatives can help avoid inefficient communication with supplier sales representatives, a common pain point for buyers. Consider attending exhibitions, one of our primary promotion channels, to meet potential suppliers face-to-face and assess their capabilities. Finally, ensure the supplier offers secure payment methods and has a transparent process for addressing any quality issues. Don't hesitate to ask for samples and conduct thorough quality inspection before placing large orders. Explore our range of WPC Wall Panel options and PVC Film Marble Sheet varieties for a comprehensive understanding of our offerings.

In Summary: Key Takeaways About High Glossy 3D UV Coated PVC Marble Sheets

- Cost-Effective Elegance: Provides the luxurious look of marble at a significantly lower cost.

- Enhanced Durability: The uv coated surface is waterproof, scratch-resistant, and easy to maintain.

- Versatile Applications: Suitable for residential, commercial, and public spaces, including walls and ceilings.

- Easy Installation: Lightweight and simple to install, reducing labor costs and time.

- Realistic Aesthetics: Advanced 3d printing technology creates stunning and varied marble patterns and veining.

- Wide Range of Options: Available in a diverse variety of colors and designs to suit any interior design project.

- Potentially Environmentally Friendlier: Can be a more sustainable option compared to natural marble, especially with responsible manufacturing.

- Ideal for B2B: Meets the needs of construction companies, interior designers, and home improvement retailers seeking quality and value.

By understanding the features and benefits of high glossy 3D UV coated PVC marble sheets, businesses can make informed decisions to enhance their projects and offerings. These innovative decorative panels offer a compelling blend of beauty, practicality, and affordability, making them a game-changer in the world of interior design and construction.